| ||||||||

|

You may redistribute this newsletter for non-commercial purposes. For commercial use contact jack@ganssle.com. To subscribe or unsubscribe go here or drop Jack an email. |

||||||||

| Contents | ||||||||

| Editor's Notes | ||||||||

|

Tip for sending me email: My email filters are super aggressive and I no longer look at the spam mailbox. If you include the phrase "embedded" in the subject line your email will wend its weighty way to me. |

||||||||

| Quotes and Thoughts | ||||||||

|

Scientists dream about doing great things. Engineers do them. James A. Michener |

||||||||

| Tools and Tips | ||||||||

|

Please submit clever ideas or thoughts about tools, techniques and resources you love or hate. Here are the tool reviews submitted in the past. |

||||||||

| Freebies and Discounts | ||||||||

|

James Grenning and Wingman Software are offering two pairs of seats for his newly released self-paced Test-Driven Development for Embedded C/C++ training course. James is the author of Test-Driven Development for embedded C and founder of Wingman Software. His courses have trained thousands of embedded software developers in TDD and SOLID design principles around the world. The introductory price is currently $500 per learner, and the course's value could be immeasurable to your career. Each prize consists of two seats so you and a colleague can learn together. The course has over a dozen exercises, ninety short videos presentations and demos, reference material as well as linked content. The best way to determine if TDD can be valuable to you, is to experience it. James' course is designed to guide you through an experience so you can decide if it can change your life. Find out more about the course here https://wingman-sw.com/training/self-paced-tdd. James is also offering a consolation prize for all entries, $100 off the introductory price. Enter via this link. |

||||||||

| Is Software The Root of All Evil? | ||||||||

|

In the last issue, a reader who wishes to be anonymous wrote:

Lars Pötter responded:

Don Herres wrote:

Here are Christoph Schmidt's thoughts:

|

||||||||

| Crashes From Space! | ||||||||

|

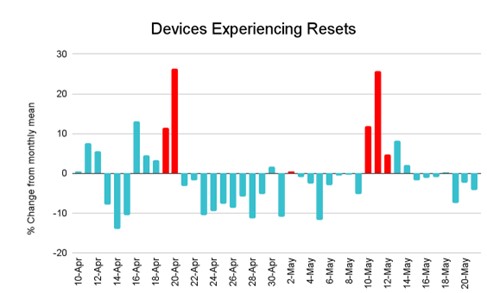

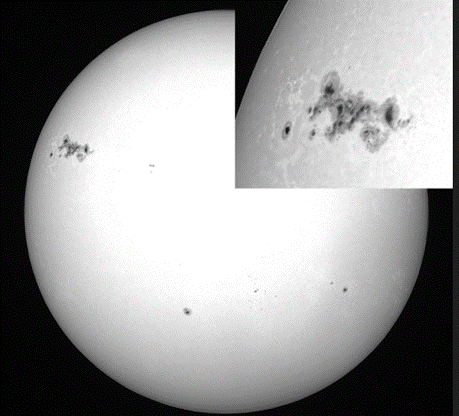

A friend for whom I have enormous respect once told me we don't need watchdog timers. "Just write perfect code", he said. While I admire his quest for perfection, even completely defect-free code is simply not good enough. Our devices face many insults, not the least an incoming rain of high-energy particles. The Oh-My-God particle in 1991 was a cosmic ray packing 3x1020 electron volts, about the energy of a baseball at 90 km/h. Thankfully those events are quite rare, but given the tiny geometry of modern semiconductors it's wise to pay attention to these threats. A watchdog timer is a must. Some developers take additional precautions, like updating GPIOs and other outputs many times per second. Memfault sells a tool that collects health and crash data from your products after they are deployed. They recently looked at unexpected resets in the devices using their technology. As you may know, we're nearing the top of an eleven-year sunspot cycle. The sun was unusually active in April and May causing dramatic auroras far to the south. Memfault's data shows resets spiked dramatically during these solar flares. For instance, look at the spike on May 11, which correlated with a major flare: I had been imaging the sun, and on that same day took this picture of solar region 3664, responsible for that flare: Sun on May 11 with inset of massive sunspot in solar region 3664. Taken with a Celestron 8 and solar filter from my backyard. The solar cycle peaks next year. Figure on a lot of flares and coronal mass ejections (CMEs) firing energetic particles at our systems. The Carrington Event in 1859 was an extreme CME that caused telegraph wires to spark, and even allowed unenergized lines to transmit messages. There was no electrical grid then; no phone lines; no satellites. Another CME of that magnitude is certain to occur, perhaps next week, perhaps centuries from now. A comparable event in 2012 narrowly missed the Earth. Few in the know expect anything other than disaster for our massively-wired planet if - when - such a storm hits us. We have built an incredible high-technology world, but it is surprisingly vulnerable to rare but unavoidable events. Hubris, alas, may be our downfall. But even absent such a high-energy event, Memfault's data shows that "space rays" (to be overly dramatic)

do pose a hazard to our systems. |

||||||||

| Toothal Tribulations | ||||||||

|

At first I thought this was a joke... but it's not. Do you need a connected toothbrush? One that can play music? It seems Procter & Gamble feels we do. A $200 version of their Oral B electric toothbrush has Alexa built in. Alas, this must-have product has been discontinued. For the unfortunate who did shell out the big bucks, the Connect app needed to configure the thing ("configure" a toothbrush???) is no longer available, so the device is essentially bricked. But not to worry: the company now has a version with, of course, AI! One can get a full-featured toothbrush for $0.99, but why not fork over $400 for a unit that, well, brushes your teeth? I wonder if these devices need time to boot up. Or if a software update mid-brush suspends operation. Is there a customer support line? A 500 page manual? |

||||||||

| Failure of the Week | ||||||||

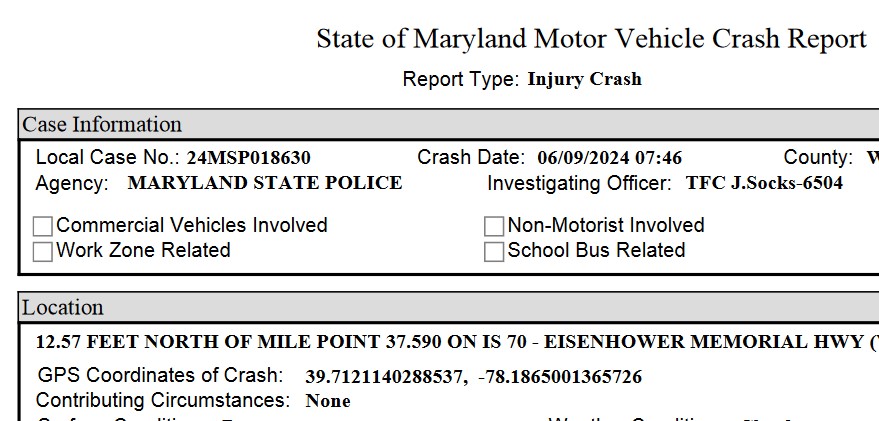

Here's a failure of common sense: This is a police report about a recent accident involving a Pennsylvanian politician. Note the GPS position, given to 13 digits after the decimal point. That's a resolution of a few nanometers. Also note that this occurred "12.57 feet north of...". Wikipedia pegs GPS's accuracy at "30-500 cm", or, at best, one foot. Those two digits after the decimal point are noise... and meaningless in a police investigation. I suspect accuracy measured in tenths of a furlong would be plenty. Roland Lemmers sent this: Have you submitted a Failure of the Week? I'm getting a ton of these and yours was added to the queue. |

||||||||

| Jobs! | ||||||||

|

Let me know if you’re hiring embedded engineers. No recruiters please, and I reserve the right to edit ads to fit the format and intent of this newsletter. Please keep it to 100 words. There is no charge for a job ad. |

||||||||

| Joke For The Week | ||||||||

These jokes are archived here. You might be an engineer if... If your father sat 2 inches in front of your family's first color TV with a magnifying lens to see how they made the colors, and you grew up thinking that was normal |

||||||||

| About The Embedded Muse | ||||||||

|

The Embedded Muse is Jack Ganssle's newsletter. Send complaints, comments, and contributions to me at jack@ganssle.com. The Embedded Muse is supported by The Ganssle Group, whose mission is to help embedded folks get better products to market faster. |