Zero-Transistor Design

Embedded.com explores the realm of complex electronic systems. Those of us who work in this field joke that we can't design anything with less than a million transistors. Datasheets can be thousands of pages documenting inconceivably complex parts.

Let's have some fun and look at a very different kind of product. Suppose you were given the task to design an autopilot. You'd probably start with a rate gyro, a microcontroller, actuators, electronic compass, and power transistors. But could you design one that uses no electronics? Nary an IC, transistor nor even vacuum tube?

I have one for my 32' boat. Yes, we have a conventional electronic autopilot that uses a flux-gate compass, computer, and motor to move the rudder. But like all autopilots, it's a power hog. One of the big challenges we face on small boats is electricity. Under power there's plenty as the alternator is spinning. But sailors prefer to sail, and if there's a breeze the engine is generally off. All of the boat's electronics and electrical gear is then powered by a pair of golf cart batteries. On Voyager they have 220 amp-hours of capacity, but we try to avoid discharging them much below the 50% mark as deep discharging is bad for lead-acid cells. It's inefficient to charge to more than about 80 to 85% capacity as the batteries can't accept many amps at that level, so we're able to reasonably use about a third of those 220 amp-hours without recharging. While sailing long distances that happens typically once every day or two.

The autopilot consumes 2 amps at 12 volts, which is a big chunk of our daily power budget. So we're faced with a conundrum: run the autopilot and not much else, charge frequently (which no one likes due to the noise), or use an alternative steering mechanism so those 50 amp-hours can be used to keep the beer cold.

Cold beer? Easy choice to make.

Take a minute and think about how you'd design a non-electronic device to steer the boat. Impossible, you say? (Note: using a crew member to steer is not an option, since it's usually just Marybeth and myself; Doing 4 hours on and 4 off 24/7 gets exhausting).

While under sail we rely on what's called a wind vane to keep the boat on course. And that is entirely mechanical with not even a single wire involved. It's a mechanical engineer's wonder, an exquisitely-built batch of bearings, stainless steel and aluminum.

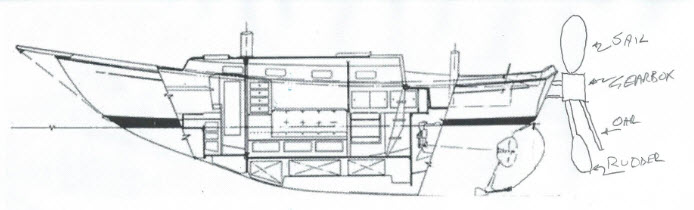

General view of the wind vane mounted on Voyager's stern. Drawing not to scale.

Once one gets more than 100 miles or so from land the wind tends to be reasonably steady over the course of many hours. The wind vane keeps the boat going on a course which is a constant angle from the wind direction. If the wind veers, so does the boat.

The sail (see diagram above) senses the wind's direction. It's actually made from some polycarbonate material and is about 3 feet long and 8 inches wide. To set the course one steers the boat in that direction and orients the sail directly into the wind. The sail is on a bearing such that it can tilt to the left or right, so if the vessel drifts off-course the sail will be blown over to one side or the other.

The wind isn't strong enough to move a rudder. The function of the gearbox is to amplify the sail's action in a very clever manner.

The gearbox links the sail's motion to the "oar," which is about 4 feet long and two inches wide. The tilting sail twists it in one direction or the other, which doesn't take much energy since the oar is so small.

Now the magic happens. The boat, oar and rudder are moving through the water. The twisting oar develops lift – a lot of lift – and it, being in a spherical bearing, moves to port or starboard. The gearbox couples that movement to the wind vane's rudder, which rotates and causes the boat to come back on course. Now, with the sail once more aimed directly into the wind, it stands upright, the oar comes back to a centered position, and the rudder also centers itself till the next correction is needed.

Water is 800 times denser than air, so the motion of the boat through the water amplifies the feeble wind energy. The energy input comes from the hundreds of square feet of Dacron sails driving the boat forward.

It sounds quite Rube Goldberg-ish but works astonishingly well. Sailors have been crossing oceans for 50 years with this sort of mechanism as their only autopilot. On Voyager we find that it will steer better than I can given at least a few knots of wind. Once, on a dark night while singlehanding to Bermuda, I came on deck to find the boat going at 8 knots, which is far too fast for this vessel; fast enough that she would have been out of control for a human helmsperson. But the wind vane was perfectly in control, and after watching things for a bit, I went back to bed. On another singlehanded trip from the Virgin Islands to Bermuda the wind was marvelously steady and I never adjusted the vane or the sails for 8 glorious days.

Wind vanes are quite expensive – on the order of $5k – more than twice the price of our electronic autopilot. I found mine at a marine consignment shop in Annapolis. At $300 it was a steal, but was very sick. The shafts were frozen; eventually a machine shop used their 50 ton press to pull things apart. The needle bearings were all shot necessitating replacing hundreds of needles. I had to fabricate some missing parts out of delrin. But my total investment was about $500.

I have a 70-year-old oscilloscope which uses only 4 tubes, including the CRT. To center the beam one moves a magnet! Radios used to have only a few tubes. The TR-1 radio used only four transistors. In the tube days TVs needed just a dozen or so active elements. Yes, modern equivalents have tons more functionality. But the engineers who built wind vanes, early electronics, and many other marvels were real wizards. I salute their creative ability to work within the limitations of the time.

Published June, 2016